How To Clean A Ruger 44 Magnum Carbine

24 Photos of Ruger 44 Carbine Disassembly, Cleaning, and Assembly

10.04.17

The Ruger Model 44 Carbine was the start long gun Bill Ruger always put into production (yep, information technology came earlier the ten/22), and it was a great gun. Drawing on traits of previous designers' creations, information technology was the epitome of a handy, useful medium-range (up to virtually 100 yards) gun for game including deer and hogs, and some would fifty-fifty say black bears. Initially called the Deerstalker, that moniker was removed after Ithaca sued Ruger. The 44 carbine was made until the early 1980s.

Officially known as the Model 44, I accept never seen ane with that proper name marked on it.

Oh, and these are Not the same every bit Ruger's afterward batter which he named the Model 99/44 Deerfield Carbine, which is not nearly as skilful a gun in my opinion.

For the first ii decades of my big game hunting, I hunted exclusively with the carbine on top in the above photo; between my father and me, nosotros took xx+ deer and at to the lowest degree 7 hogs with 44 carbines over the years — and never lost a 1.

While they are great trivial guns and are usually reliable, they do demand the gas system cleaned out every few decades. This will tell you how to thoroughly clean your carbine in as simple linguistic communication as I tin can manage.

As nosotros walk through the process, nosotros volition look at 2 rifles; ane was made very early and the other, much later. There are some differences, and yous do NOT desire to mix-and-match parts between guns of different vintages if y'all can aid information technology.

Afterward making sure your carbine is unloaded, you'll need to remove the barrel band. These were fabricated using screws with coin-slotted screws; the screwdriver slot is curved and thick and then you can supposedly remove it using a coin. Good idea on paper; not bully in exercise. You'll do well to find an old cheap screwdriver and grind it to fit, as I've done above. Otherwise the screwdriver WILL sideslip and gouge your stock, the band, yourself, or all of the to a higher place.

Anyhow, loosen the screw and slide the ring forward and off, only don't remove the barrel & activity from the stock until you read the next stride.

To remove the barreled action from the stock safely, pull the bolt to the rear and let it to lock open up. Next, lift the forepart of the barrel upward and allow the lug at rear of receiver to swivel up and out of the recoil block, which is a metal piece that stays attached to the stock.

In that location are some pins in the receiver which may now try to fall out, because they fit loosely, then picket out for that.

Normally, this is as far equally you need to go for cleaning. Simply if yous desire to clean the gas system, keep reading.

Both carbines in the photo above accept their deportment locked open; the one on peak is the newer 1.

If you need to dig deeper — and if you lot are truly capable of it — proceed past removing the trigger associates. Close the action SLOWLY (never allow information technology slam except when chambering a circular).

Ruger calls the bolt release a "lifter latch," and information technology'southward on the lesser of the receiver just in forepart of the trigger guard. Printing it upward to release the bolt.

Place the safety in the "safe" position.

Button out the rear pin, as shown to a higher place, and motion the associates towards the back of the gun well-nigh one/viii″, then bring it down out of the receiver. Handle the activeness & barrel assembly carefully, and so it doesn't accidentally come apart.

Ya know how easy it's been and so far? That'south about to modify.

Turn the gun upside-downwardly and shrink the action spring so the spring'southward tension is being restrained by your mitt rather than by the shoulder at rear of receiver. While doing that, you'll have to slide the slide towards the receiver about ane/4″ and lift its rear end out and off of the commodities; at this betoken the bolt handle ought to pretty much fall out (if it doesn't, just use a punch and small hammer to persuade the bolt handle to come out).

The actions are in opposition; y'all have to pull the jump forward and and then motion the slide rearward. Catchy, only you can do it.

Keep the gun over a table while you practise this, to take hold of all the parts that may fall out… like the gas piston, which is at present gratis to fall out of the gas block/cylinder that's on the bottom of the barrel.

Your parts ought to look like this now.

There's ordinarily no reason to remove the ejector, but it's in the way of removing the bolt. And then I just used a piffling screwdriver to concur the spring-loaded rascal out of the way. If y'all can't get the screwdriver started under it, utilise a tool to push it from the within of the receiver.

Don't go nuts here… likewise much can ruin the ejector. You simply desire to motility it far enough to clear the bolt.

Flip the receiver upside-downwards. Rotate the bolt towards the ejection opening in the receiver and move it about halfway to the rear (every bit shown in the flick above). At present you can elevator it out of the receiver.

To reassemble, contrary these steps. Oh, and don't take the commodities apart.

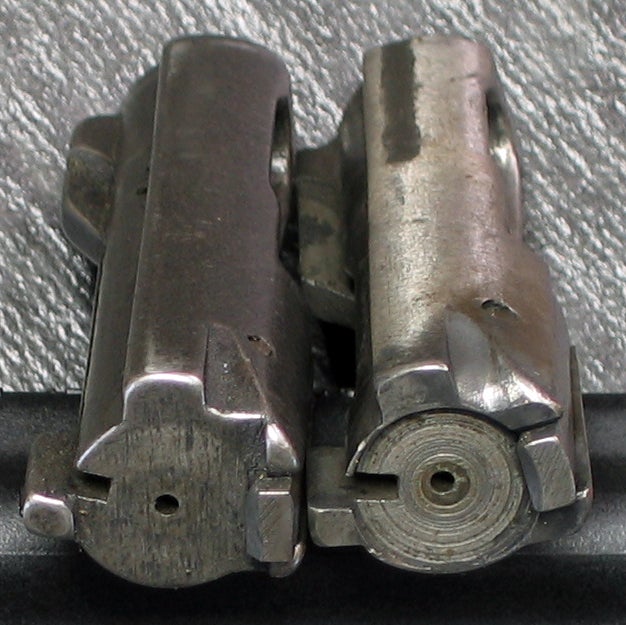

Just a pic to show the differences betwixt the bolts from a newer (left) and older 44 carbine.

There's a office — which the end of the screwdriver is resting on in the photo above — called the cartridge guide plate. If this is loose, you will accept ammo feed problems.

Information technology is non present on all 44 carbines, so don't freak out if information technology's not there… merely if it is, make certain it'due south practiced and tight. 2 screws hold information technology in place; their heads tin can exist accessed on acme of the receiver.

If you lot have gone this far, you probably have feed problems. Oft, this is caused by gunk here in the gas port and piston area.

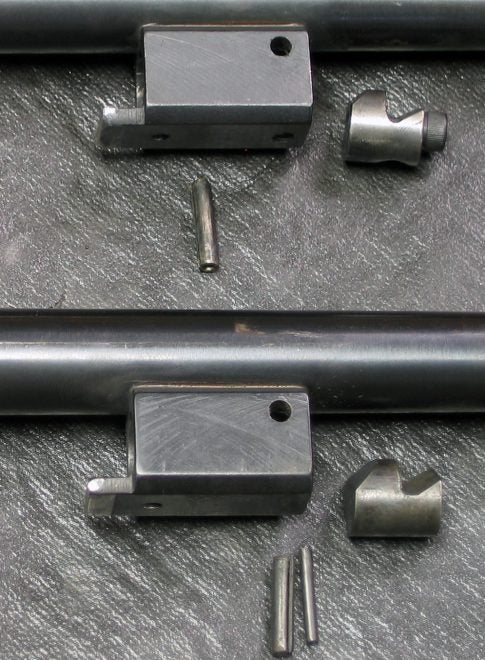

The piston block plug is held in identify by ii roll pins, i within the other. You can drive these out separately or every bit a unit; I tried it both ways and information technology didn't actually matter.

Now you can drive the plug out towards the front end of the gun.

Clean all the black skank off of all these parts, including the piston (not shown) and the inside of that block that's welded to the barrel.

The gas port is an angled hole which was drilled through the steel block as well equally the lesser of the barrel, so you lot can easily clean out the crud. I start with something like a wood toothpick (forest won't scratch the steel) and follow up with pipe cleaners & solvent. Whatever information technology takes to become information technology clean without scratching things up.

Fourth dimension to reinstall the piston block plug, which is probably a tight fit. Go it started, making sure it'southward turned then the cutout will line upward with the pivot hole. Knock it on in using something softer than steel, such every bit this brass hammer or a block of wood, etc..

Bulldoze the roll pins in from either side, tapered end starting time.

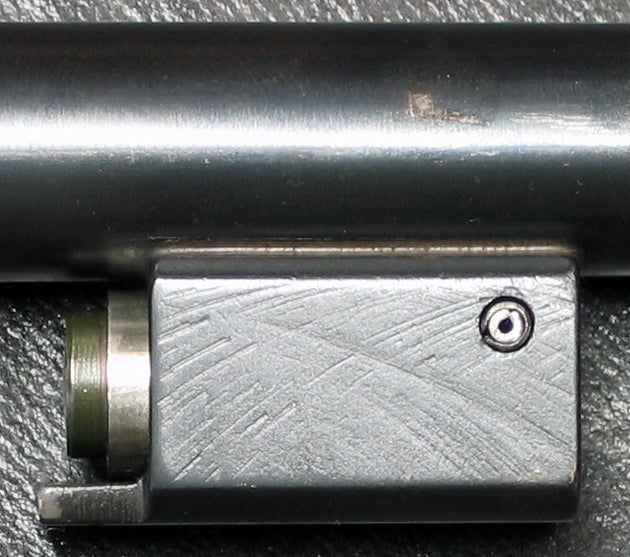

One time the plug is installed correctly, information technology should look like this.

This bolt is properly installed and ready for further assembly.

The gas piston is pretty small, but information technology'southward vital; don't forget to install it.

Of grade yous've cleaned the mag, springs, and all related parts, and wiped them with an oily rag.

Encounter photo above for the proper orientation of the magazine tube to the barrel. Brand sure the top of the magazine tube goes towards the barrel; this is indicated past the plug at forepart end of mag tube. The slot is cut beneath center of that plug, and then the largest part of the plug is the top, or barrel side.

Exist sure your bolt handle is nearby.

Offset, place the slide into the receiver and install the commodities handle. Now, slip the mag and action spring through the slide and into position on the gas cylinder block, compress the action spring, and lower the rear of the mag tube to the receiver, allowing the bound to engage with its spot at front of receiver — so install the trigger assembly.

You may wish to use a zip-necktie well-nigh the rear of the magazine tube to hold the leap compressed during assembly, then carefully cut it after the trigger group is in place.

This trigger group is virtually in place, but not entirely. It must now be slid forward so the pin can be installed at the rear (run across how the holes don't line up?).

Be aware that the hammer must be cocked before installation. Do yourself a favor and put the safety on, as well.

Pivot installed but notwithstanding protruding. We're almost home!

Pull the bolt handle to the rear and allow the activity to lock open. Make sure all the receiver pins are affluent with the sides of the receiver, then hook the lug at rear of receiver into the recoil block and lower the front end of the barrel towards the stock.

Next comes the barrel band. Don't put it on backwards! The mold marks (those little circles molded into information technology) should be placed rearward, so they're not visible afterwards the band is installed.

Spread the band as yous slide it domicile, so you lot don't scratch your stock. And of course, tighten up the spiral.

Done! Now y'all can hitting the range with some ammo — these guns were designed to be used with 240-grain jacketed bullets — and effort out your popper.

Happy hunting!

Source: https://www.alloutdoor.com/2017/10/04/24-photos-ruger-44-carbine-disassembly-cleaning-assembly/

Posted by: caricoevelf1974.blogspot.com

0 Response to "How To Clean A Ruger 44 Magnum Carbine"

Post a Comment